Here we will discuss COB (chip on board) type LEDs.

COB is an abbreviation for “Chip On Board,” which means a structure in which a chip is mounted on a board, and is one of the package types for LEDs.

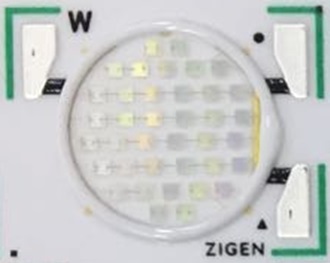

COB LEDs usually have electrodes placed at the corners of a square substrate and a circular light-emitting part in the center.

If you draw it in a picture, it has a cross-sectional structure like this.

Here to see what the inside looks like without the phosphor. You can see that there are many blue chips on the board, and each one is connected with a thin wire.

Merit of COB devices

COB has various advantages such as

- Emit high output light with high luminous density

- High heat dissipation as the chip is mounted directly on the board

- Drive voltage can be adjusted

- The shape of the light emitting surface can be changed to suit the purpose

- Excellent controllability of emitted color

- Easily mix colors even when emitting multiple colors発光密度の高い高出力光を出せる

To explain each in detail,

1.Emits high output light with high luminous density

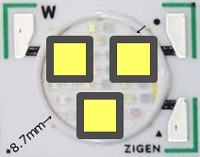

In one example of our COB, a resin area with a diameter of 8.7 mm can be driven with 12 watts and can emit over 1600 lm of light.

However, when using general surface-mount type LEDs, for example, if the size is 3030, only three can be mounted on a diameter of 8.7 mm. Even if each was driven at 1 watt, it would be 3 watts, and the difference in luminous flux obtained would be overwhelming.

2.High heat dissipation as the chip is mounted directly on the board

COB LED chips are mounted directly on the board.

Ceramic substrates and aluminum substrates are mainly used for COBs, and both are materials that are resistant to heat and have excellent heat dissipation. It has the role of effectively diffusing heat (about half of which is converted into heat) into the heat sink.

In particular, the Japan domestically produced ceramic substrates we use have a proven track record of over 10 years in COB and boast excellent stability.

3.Drive voltage can be adjusted

As shown in the cross-sectional diagram, each LED chip is connected with gold wire.

How many LED chips should be connected in series with gold wire? Therefore, you can obtain a voltage of approximately 3V x the number of LED chips in series. (At our company, we mostly use 9V, 15V, 18V, and 36V)

There are required current and voltage values depending on the power source used, but with COB it is possible to respond flexibly by simply changing the way the gold wires are connected.

4.The shape of the light emitting surface can be changed according to the purpose

Generally, the external shape of COB is 12×15, 13×13, 19×19, 28×28 (mm), and the light emitting surface is circular.

However, depending on the application, there may be requests such as emitting high-power light in a rectangular shape. In addition, various shapes of light emission are possible.

We have a track record of mass producing elongated shapes with a light emitting surface width of 2.2 mm (length approximately 7 mm), and can accommodate a variety of shapes. (You need to prepare the board specially)

5.Excellent controllability of emitted color

LEDs can create a variety of colors by combining blue LEDs and phosphors.

In general, it is often adjusted to white light, but by finely controlling the amount of phosphor per device, it is possible to suppress variations in chromaticity point.

This is actually an example of our device, but there are also models that are produced with a variation level of Step 1.5.

The point is that COB is actually produced with a narrower variation in color than the specification frame, so the emitted colors are more consistent.

Surface mount types are shipped by binning, which allows for a relatively large color variation, so there is a possibility that a certain amount of edges of the frame may be mixed together within the shipment.

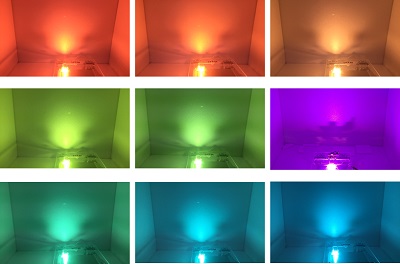

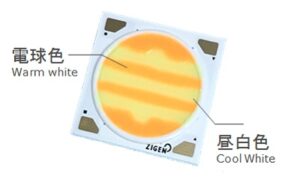

6.Easy to mix colors even when emitting multiple colors

Furthermore, using our patented color control technology, we manufacture many COB devices such as the ZG2 and ZG6 series that can accurately control the colors of light bulb and white phosphor resins.

By gathering multiple colors in a narrow light emitting area, it is possible to suppress the occurrence of color breakup due to light passing through an optical system such as a lens, and it is possible to suppress color mixing compared to lining up two types of surface mount types. This is an LED solution with excellent performance.

We will offer a COB that suits your application and power source.

We customize and manufacture COBs for various purposes, such as wanting to create a COB that matches this power supply, wanting light of a certain color, or wanting to increase the color rendering to 95 or higher.

Especially, we know matching with power supply and heat management system is always the key forlighting products.

One of our strengths is that we can offer the most optimal and cutting-edge proposals globally.

Please feel free to contact us from the contact page.